Data is all around us.

The Internet of Things (IoT), through sensors and devices, have the ability to produce large volumes of data while artificial intelligence (AI) can learn patterns in the data to automate tasks for a variety of business benefits. AI can automate repetitive learning and discovery through data. AI can add intelligence to existing products. AI can adapt through progressive learning algorithms to let the data do the programming. AI can find structure and regularities in data so that the algorithm acquires a skill. AI analyzes more and deeper data using large volumes of data to train deep learning models. AI, fed more and more data, yields more accurate data driven results. Simply, AI helps you get the most out of your data. When algorithms self-learn, the data itself becomes the business’s intellectual property (IP). All answers are in the data. You just need to deploy AI to find the answers. Since the role of the data is now more important than ever before, data and AI create new competitive advantages. If you have the best data in a competitive industry, even if everyone is applying similar techniques, the best data and resulting AI will win.

As technology costs have fallen and the sophistication of IoT devices have increased, it is easier to generate data on the performance of buildings and the systems of systems within them at a more granular level. At its core, IoT enables different components to communicate with each other with little to no intelligence. This lack of intelligence means that a building may generate a deluge of data that needs to be manually sifted through to glean operational insights, proficiencies, and advantages. It is these characteristics that underscore how commercial buildings benefit from disruptive technologies like AI – turning data into actionable information to aid facility operations and personnel. Without data, IoT, and AI, the combing of data to generation actionable intelligence is either time-consuming, human involved, costly, or (often) deemed useless.

But today, there are several business drivers that can be powered by an AI enabled solution that provide competitive business advantages:

Predictive Energy Optimization

Traditional tools that are used to manage energy consumption are

reliant on “after-the-fact” reporting essentially analyzing what energy was used to then propose an operational change in the hope that less energy may be used next time. AI and predictive analytics are disrupting this reactive approach in favor of a more proactive data driven approaches.

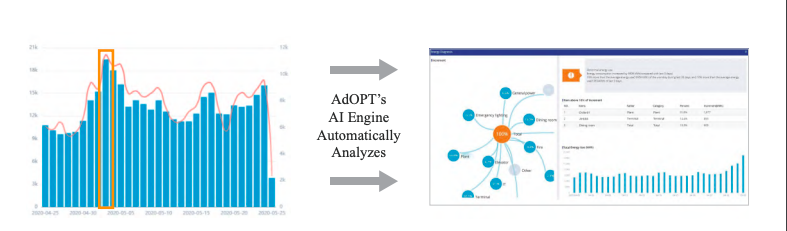

One of the features on the AdOPT platform is autonomous diagnostics on whole-building energy performance leveraging

available data feeds from building automation and sub-meter systems. AdOPT provides unprecedented insights on what

causes variations in monthly energy bills by analyzing — in a quantitative way — how independent variables such as weather, people movement, and operation sequence impact the energy use of each building subsystems or individual

building equipment. Once configured, AdOPT’s AI engine is able to automatically perform such analytics to inform

decision making in real time and at a scale that would require an army of data scientists.

This AdOPT feature is possible because of the AI engines’ unique capability of handling non-linear and multi-dimensional processes which are typically found in building systems. Traditionally, engineers are accustomed to performing rough estimation on energy performance with elementary tools such as spreadsheet-based regression models which usually deviate considerably from real conditions (especially over time). With coupled, unsupervised and supervised learning and inference skills, AI models nonlinear and multi-dimensional systems in an accurate way – outperforming what most human experts do when facing dozens or even hundreds of operating variables that have direct and indirect relations with energy performance. Simply, AI helps you get the most out of your data.

Preventative Maintenance and Fault Detection

Traditional maintenance and fault tools are based on rules or adherence to schedules. Applying AI to automated fault detection and diagnosis (AFDD) can enable accurate detection of faults in the equipment and systems placed under its surveillance and greatly reduce or eliminate false alarms that can plague rule based AFDD. Upon detecting a suspected fault, AdOPT’s AI engine will further provide expert with timely diagnosis of the underlying cause, helping maintenance staff ensure that buildings perform effectively and efficiently.

Rule-based methods, typically part of expert systems, are one of the earliest developed AI techniques to make decisions in

a variety of industrial applications. A rule-based method is developed on the basis of knowledge from domain experts and

usually represented in logical combination of multiple “if-then” rules and assumptions. A simple example is threshold

settings of equipment or system operation in which a decision is made to trigger an alarm if one or a few operating

parameters are over or below predefined values. Today, rules-based analytics accounts for the majority of offerings in the

building analytics market.

Another unique feature of AdOPT platform is AI enabled AFDD to autonomously probe the source of detected faults. For example, a fault is detected in an air handling unit (AHU) – the supply air temperature was significantly over the set point. There are multiple probable causes that resulted in the fault: high coil discharge air temperature, high chilled water supply temperature, supply air flow too high, etc. AdOPT’s AI is able to trace the fault to the source over the entire system – it was high evaporative temperature, due to overheat of the refrigerant at the chiller evaporator!

Valuing AI v.s. Rule Based Methods

Disadvantages of non-AI, rule-base methods are conspicuous due to its notorious knowledge acquisition problem. In almost every industry, there is a shortage of experts making it very difficult to obtain the knowledge. Even if the knowledge is available, it can be difficult and expensive to document and digitalize. Non-AI rule-based methods tend to be custom and don’t scale well because the expertise and knowledge (library and models) required varies from device to device and system to system, especially as conditions change and equipment deteriorates. A successful knowledgebased automated system calls for both domain expertise and programming skills.

Not until recently has AI emerged to solve the issues of standardization and generalization, highlighting the feasibility of acquiring knowledge with minimal, and in some instances no, human expertise. To achieve this, machine learning algorithms have been designed and developed to recognize patterns and extract insights from data instead of simply applying knowledge and principles directly. In the example of threshold setting, AI makes decisions in a much smarter way than a rule-based method. The low-high limits are often set by engineers’ experience and may take a while for the engineer to manually adjust them in properly. By coupling machine learning and time series analytics, AI precisely tracks data trending by “learning” data patterns from historical operation and makes decisions dynamically, regardless of the variation in operating conditions.

The AdOPT AI Engine delivers smart services to users. As data analytics and data driven solutions become increasingly useful in IoT applications, AdOPT has implemented an AI Engine that’s been designed and developed with R&B’s proprietary expertise to handle the challenges posed by energy and facility management (including extreme data scarcity and quality issues).

For example, AdOPT’s AI Engine performs back-end data cleansing, object network, feature extraction, optimization & decision-making, and interpretation. Leveraging these functions, AdOPT’s AI Engine automatically runs multiple service modules, such as prediction and abnormality detection, to provide building owners and operators data driven recommendations. Overall, AdOPT’s AI Engine is purposefully designed to automatically provide support to end users through engagement AI-based algorithms and domain knowledge.